The Process of Medical Component Injection Molding

At Excel Medical Products, we understand the critical role that high-quality, reliable medical devices play in patient care. With our state-of-the-art injection molding facility and team of skilled professionals, we are dedicated to delivering thermoplastic molded parts that meet the stringent requirements of the healthcare industry.

Thermoplastic injection molding, a widely employed manufacturing process in the medical device industry, allows for the production of intricate and precise components with exceptional dimensional accuracy. Injecting molten thermoplastic material into a mold cavity offers numerous advantages, such as the ability to create complex geometries, cost-effectiveness, and short production cycles.

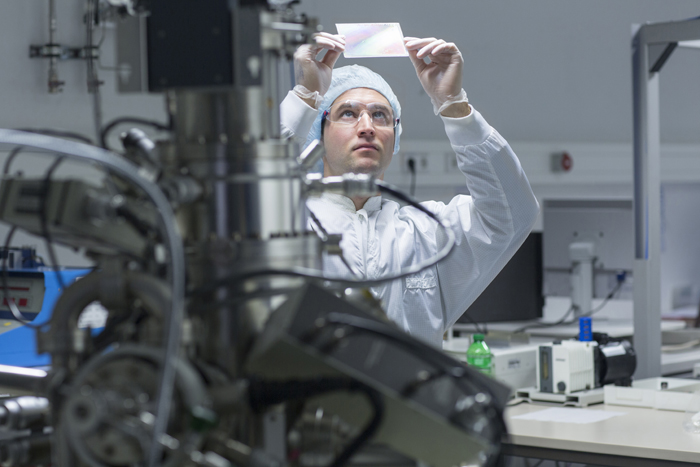

In addition to our commitment to excellence in manufacturing, Excel Medical Products adheres to the highest quality standards. We proudly maintain an ISO 8 cleanroom environment, ensuring a controlled atmosphere that minimizes the risk of contamination during the molding process. This dedication to ISO 8 standards is pivotal in meeting the stringent regulatory requirements of the medical device industry and ensuring the safety and efficacy of our products. In this article, we look to answer key questions regarding the thermoplastic injection molding process.

What Is Thermoplastic Injection Molding?

Thermoplastic injection molding is a highly efficient manufacturing process for plastic parts. It involves injecting molten thermoplastic materials into a mold cavity under high pressure, allowing for the creation of designs that include complex shapes and details.

To start the process, a thermoplastic resin is selected for its desirable properties like strength and durability. The resin is melted and injected into a precisely designed mold using an injection molding machine. The molten plastic fills the mold, taking its shape.

Once filled, the plastic cools and solidifies within the mold. The mold is then opened, and the finished part is ejected. Additional post-processing steps may be done, such as trimming or surface finishing. Thermoplastic injection molding offers efficient production of high volumes of parts with consistent quality. The process is fast, reducing lead times and enabling quicker market entry. It supports complex designs and provides design flexibility.

Partner With Excel Medical Products Today

With extensive molding capabilities and knowledge of the process, Excel Medical Products has the right combination of equipment and experience to bring your component designs to life. Contact us today for all your Thermoplastic Injection Molding, Insert Molding and Over-Molding needs.